Understanding the Importance of Timely Stretch Cover Device Repair Service Solutions

When it comes to stretch wrap machines, timely repair work can make all the distinction. What aspects should you take into consideration to assure your machines remain in leading form?

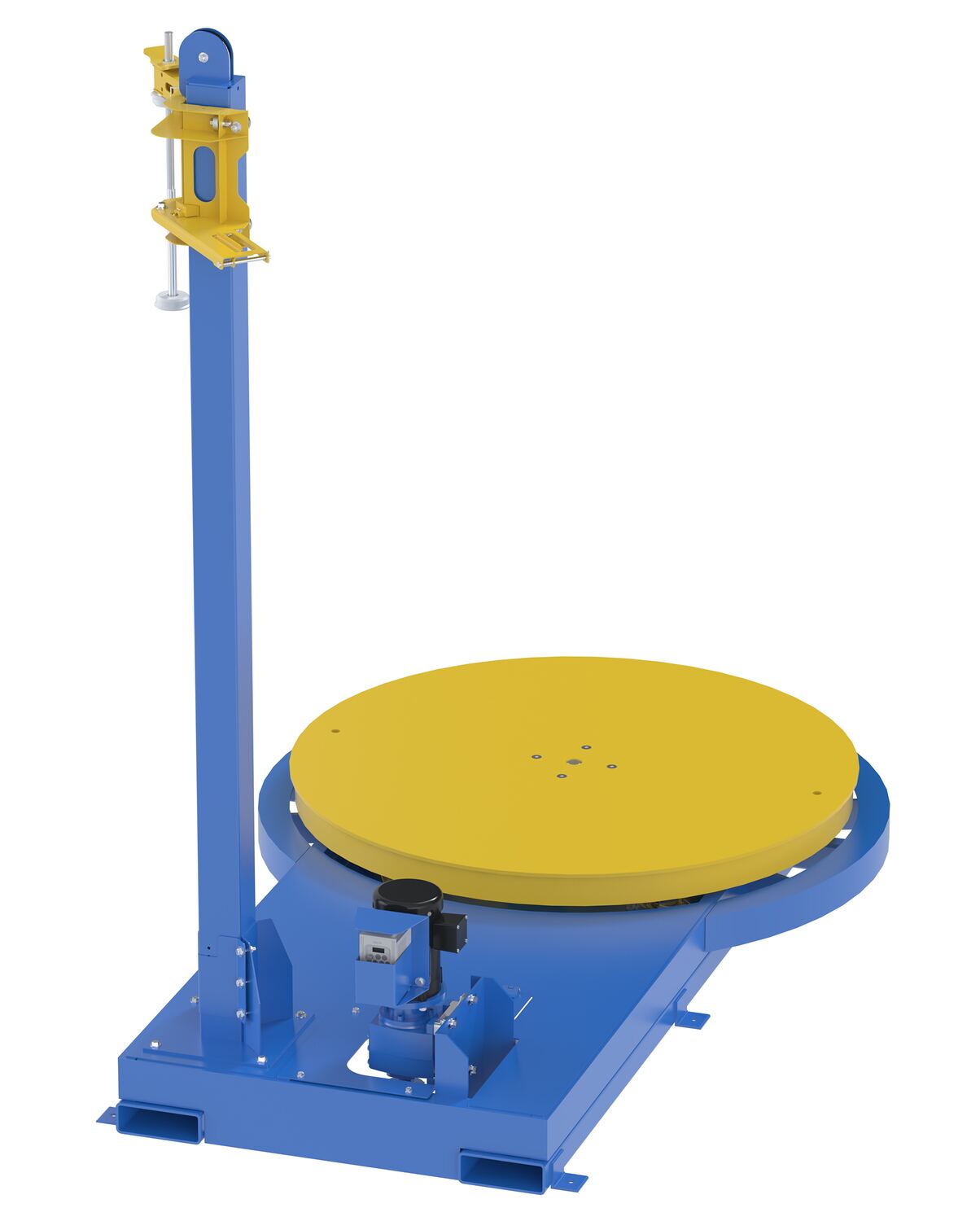

The Function of Stretch Wrap Machines in Modern Manufacturing

Stretch cover equipments play a necessary role in modern manufacturing by ensuring that items are firmly packaged for transportation and storage. You rely upon these devices to offer stability and protection, avoiding damage throughout transportation. When you utilize stretch wrap, you minimize the threat of things moving or getting crushed, which can bring about pricey losses.

Moreover, making use of stretch wrap equipments can enhance your total supply chain effectiveness. By simplifying the packaging process, you decrease labor expenses and accelerate distribution times, guaranteeing that your clients obtain their items immediately. In today's hectic market, this advantage is essential.

Usual Problems That Cause Device Downtime

When your stretch cover machine experiences downtime, it can often be mapped back to mechanical failures or driver errors. Recognizing these common problems can aid you prevent costly disruptions. By resolving these factors, you can maintain your procedures running smoothly.

Mechanical Failures and Break Downs

When parts put on down or break, your stretch cover device may stop all of a sudden, affecting productivity. Additionally, electric failures can cause malfunctions in the device's control system, creating more delays. By focusing on prompt repair work, you're not only lowering downtime but additionally prolonging the lifespan of your equipment.

Driver Errors and Oversights

While drivers play an important function in the smooth performance of your stretch wrap maker, their mistakes and oversights can lead to substantial downtime. Usual issues like improper loading, incorrect settings, and failure to monitor wrap tension can cause delays and product damages. Inevitably, spending in driver training pays off by boosting performance and lengthening your equipment's life-span.

The Financial Effect of Postponed Repair Services

Postponing repair services on your stretch cover device can result in considerable financial consequences that ripple via your whole procedure. When your maker breaks down, efficiency plummets. Each hour of downtime can cost your company not just in lost result, yet likewise in labor costs as employees stand idle. You could likewise deal with increased product wastefulness because of improper covering, causing higher costs for product packaging materials.

In addition, prolonged delays can rise minor issues into significant troubles, needing much more comprehensive repairs or even full substitute of the machine. Eventually, prompt fixings are vital to keeping your base line and ensuring smooth operations.

Benefits of Proactive Maintenance Programs

Timely repairs can conserve you from expensive downtime, but applying an aggressive maintenance program takes it an action additionally. This not only maintains your stretch wrap machine running efficiently but additionally prolongs its lifespan.

With fewer disruptions, your labor force can concentrate on their tasks without the tension of unexpected equipment failings. Maintaining peak performance can enhance the high quality of your covered items, ensuring customer complete satisfaction.

Determining Indicators That Your Equipment Needs Repair

As you run your stretch cover maker, it is vital to stay alert for indications that indicate it might require repair service. If the film isn't adhered appropriately or you observe unequal tension, your equipment may be malfunctioning.

One more sign is an increase in downtime. If your machine frequently quits or needs adjustments, it is time to investigate. Maintain an eye on the device's rate; if it's slower than normal, something might be incorrect. Any noticeable damage like torn cable televisions or leakages ought to not be overlooked. Immediately dealing with these indicators can avoid extra considerable problems down the line, ensuring your operations run efficiently.

Choosing the Right Repair Work Solution for Your Needs

Just how do you pick the ideal repair solution for your stretch cover equipment? First, consider their experience and proficiency. Search for specialists who specialize in stretch cover devices and have a tried and tested performance history. Examine online evaluations and testimonials to determine customer complete satisfaction.

Next, evaluate their reaction time. A trustworthy service must supply punctual assistance, as machine downtime can be expensive. It's additionally important to understand if they offer emergency situation repair work.

Don't fail to remember to ask regarding service warranties on repairs and parts. A credible solution guarantees their work, offering you peace of mind.

Lastly, contrast rates yet stay clear of selecting entirely based on cost. Sometimes, the cheapest option might cause below average service. By considering these factors, you'll locate a repair solution that satisfies your needs and keeps your stretch cover maker running smoothly.

Strategies for Minimizing Stretch Cover Maker Downtime

Educating your drivers is another crucial approach. Equip them with the understanding to recognize and deal with minor problems prior to they lead to considerable failures. Encourage them to keep a log of any type of abnormalities, which helps in diagnosing problems much faster.

In addition, maintaining an inventory of necessary extra components can drastically lower downtime. When something breaks, having the right parts available suggests you will not need to await deliveries.

Lastly, consider purchasing real-time tracking systems. These systems can inform you to efficiency modifications, enabling try this website prompt treatment. By applying these approaches, you'll maintain your stretch cover equipment running efficiently and successfully.

Regularly Asked Inquiries

Just How Often Should Stretch Cover Machines Be Serviced?

You need to service stretch cover equipments regularly, ideally every 6 months. Nonetheless, if you see any kind of efficiency problems or unusual sounds, don't wait-- schedule upkeep immediately to stop pricey failures and ensure peak effectiveness.

What Are the Typical Prices Related To Stretch Wrap Machine Fixes?

Common costs for stretch cover device repairs differ, but you could expect to invest in between $200 to $1,500 relying on the problem. Normal maintenance can aid lessen these costs and extend your equipment's lifespan.

Can I Do Basic Upkeep on My Stretch Wrap Equipment?

Yes, you can do basic upkeep on your stretch wrap maker. Routinely examine for deterioration, cleanse the elements, and warranty proper lubrication. Maintaining it healthy can expand its life expectancy and boost efficiency.

Just how Do I Know if a Repair Work Solution Is Trusted?

To locate a credible repair service, examine online evaluations, request site web for recommendations, and confirm qualifications. A reputable solution will certainly provide clear price quotes, service warranty options, and timely interaction, guaranteeing you feel confident in their know-how.

What Should I Carry out in Case of an Emergency Maker Failure?

In instance of an emergency machine break down, you must quickly stop operations, evaluate the problem, and contact your repair work solution. Maintain important call numbers handy, and document the problem for efficient repairing when aid gets here.

Final thought

To sum up, comprehending the importance of prompt stretch wrap machine fixings can considerably enhance your procedures. Keep in mind to remain attentive for indications of wear and pick a trustworthy repair work solution to keep your equipments running smoothly.

Comments on “Operators should be trained to spot signs that indicate stretch wrap machine repair is needed.”